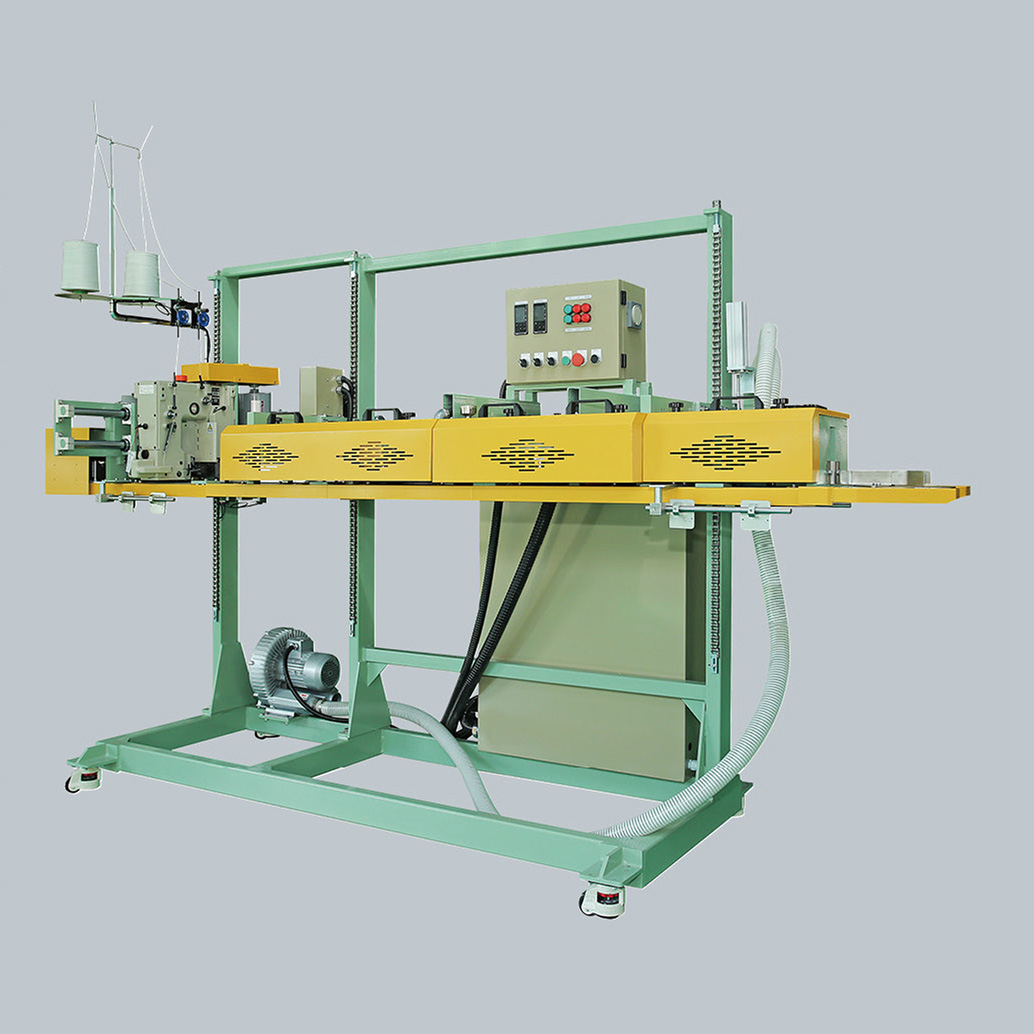

YT-BZR-3编织袋热合封口机

Product Details

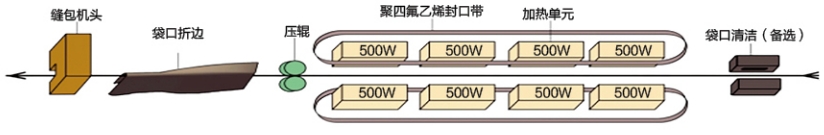

工作流程/Working process:

热封缝合工作流程:袋口清洁(备选)→内袋热封(4组加热块加热:聚四氟乙烯封口带使加热块与袋子不直接接触,以保护袋子外表不与加热块粘连)→压辊压合→袋口折边→缝包机:外袋缝纫特点:此单元采用控制器、电机变频调速控制器、加热系统检测器件构成控制系统的主体,实现整个热合机的协调控制。系统具有加热系统检测、自动报警停机、故障显示功能,并有完善的故障保护及连锁停机功能。整个操作系统使用简单,功能完善,便于检修和维护。整机由自动导入装置、自动热封装置、自动折边缝包装置及现场控制柜组成。实现热封内膜、外袋折边缝口一体化完成,有效提高工作效率并减少人工成本。

Working process of heat sealing and sewing: bag mouth cleaning (optional) → heat sealing of inner bag (heating of four groups of heating blocks: Teflon sealing tape prevents the heating block from contacting the bag directly, so as to protect the bag surface from adhesion with the heating block)→ pressing roller pressing →bag opening folding →sewing machine: sewing characteristics of outer bag: this unit uses controller, motor frequency conversion speed regulation controller and heating system detection device to form the main body of the control system, Realize the coordinated control of the whole heat sealing machine.The system has the functions of heating system detection, automatic alarm shutdown, fault display,and perfect fault protection and interlock shutdown. The entire operating system is simple to use, complete in function, and easy to repair and maintain. The whole machine is composed of an automatic induction device, an automatic heat sealing device, an automatic folding sewing device and a field control cabinet.Realize the integration of heat sealing inner membrane and outer bag folding seam, effectively improve work efficiency and reduce labor costs.

Prev:YT50自动抱袋+自动输送折边缝包机组

Next:NO